There are lots of options you can use when you need the ideal movement in an engineering scheme. Aside from making a decision, some other steps are vital to ensure that you get the best. Also, there is a need to take the needed space limitations, performance, or technical specifications into cognizance.

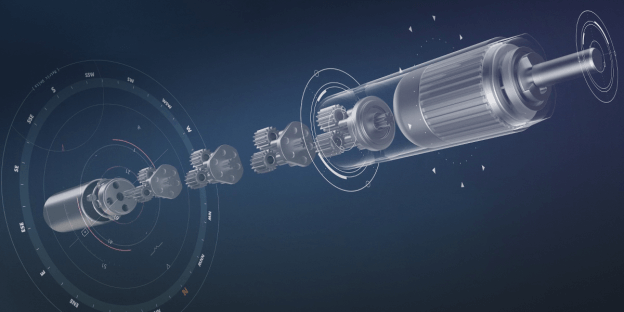

The small planetary gearbox units consists of gears that have a unique disposition from other models. Examples of these units are the helical gears, cyclical or spur, and uncrowned end. What methods are the best in categorizing these elements?

Sun: This part of this piece of instrument functions as the central gear. It rotates on the central axis and has a larger size.

Ring or Crown: A planetary gearbox contains an outer ring (with the inner side carrying its teeth) that interlocks with the satellites. This ring includes the entire epicyclical train. Also, for the outer ring, its core can be the epicenter of rotation, so that the directions can easily be changed.

The Planet Carrier: The primary function of this part is to hold up to three times the size of the gears. The planet carrier interlocks with the sun gear.

![]() What Are The Major Benefits Of Planetary Gearbox?

What Are The Major Benefits Of Planetary Gearbox?

Increased Repeatability

The advantage of increased repeatability is one of the significant benefits of a miniature planetary gearbox. Its higher axial load and speed radial offer robustness and reliability. The overall result becomes that the gear’s misalignment is effectively minimized. Also, low vibrations and uniform transmission at different loads offer ideal repeatability.

Greater Durability

Miniature planetary gearboxes are also characterized by higher durability. This is attributable to their better rolling ability and their torsional rigidity. To make this feature better, your bearing will help decrease the losses that are prone to happen by the box and the shaft rubbing directly on themselves. When this is done, the planetary gearbox achieves a greater efficiency so that a very smooth overall operation is achieved.

High Level of Efficiency

The truth is that everyone wants a highly efficient system to save the demands for increasing energy uses. The best news is that planetary gearboxes are better at it. Theses reducers provide greater efficiency, and this is attributable to its internal layout and design. During their operations, there is an excellent minimizing of losses. In fact, in recent times, drive mechanisms such as these are prominent for offering greater efficiency.

Decreased Noise Level Due to More Surface Contact

In miniature planetary gearbox, jumps are nonexistent, and rolling is very much softer.

Increased Transmission of Torque

Because these systems have teeth in contact, the mechanism can withstand and transmit more torque. To cap it, it does it in a more uniform style.

Final Thoughts

These highly efficient systems are the best choice for a perfect engineering movement scheme. We believe this article is an answer to your questions about the top reasons why you have to use miniature planetary gearbox systems.