There are many benefits to implementing CNC machine tolerance in contemporary production processes. The main advantages are precision and accuracy, which guarantee that machined components closely follow designated dimensions and tolerances. This accuracy improves the overall performance and quality of the product by producing results that are reliable and reproducible. Notable benefits include efficiency and cost-effectiveness, which minimize material waste and rework.

CNC machine tolerance results in satisfied customers, precise, high-quality items, and a competitive advantage in the market.To study more about CNC Machining click here. Clearly defined tolerances make assembly simpler and allow for part interchangeability, which speeds up manufacturing and increases design flexibility. Adherence to tolerance norms guarantees regulatory compliance, which is especially important in sectors where accuracy and safety are critical.

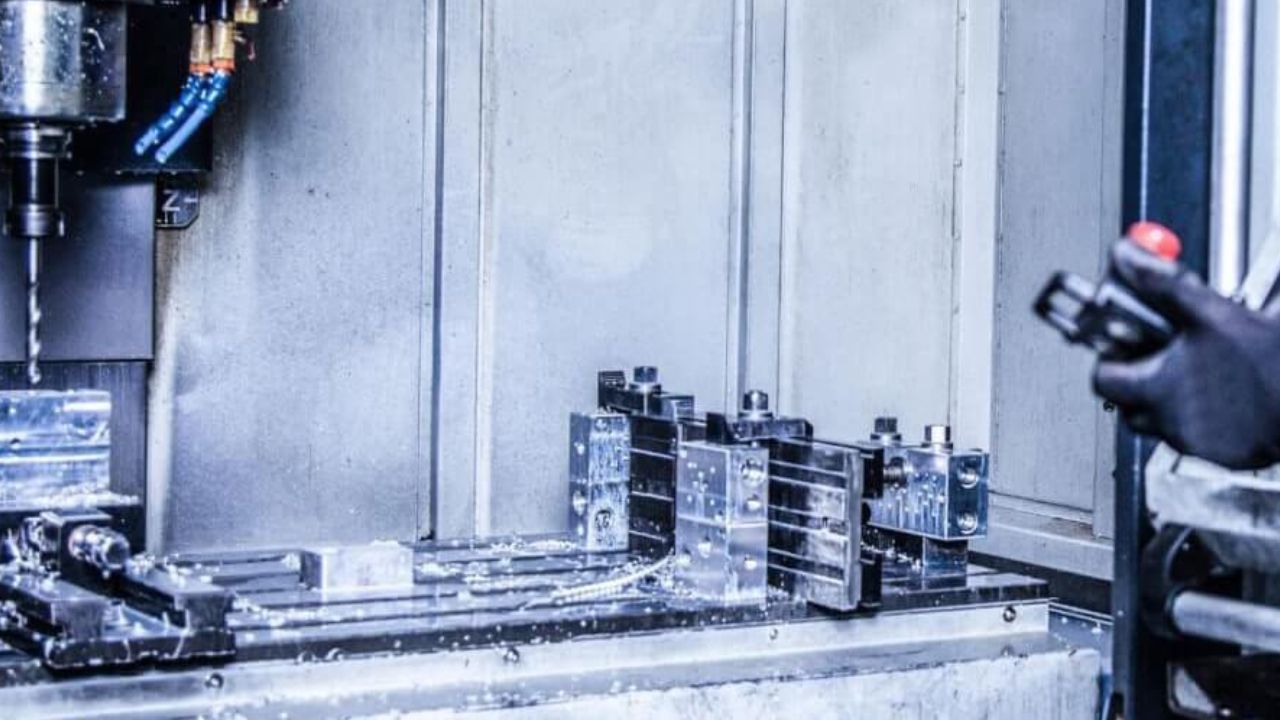

CNC Machining Tolerance’s Principal Benefits

There are numerous benefits to using CNC machining tolerance, and these benefits have a big influence on the production process’s efficiency, dependability, and quality. These benefits increase overall productivity and cost-effectiveness while also guaranteeing exact adherence to design specifications. The following are the main benefits of CNC machining tolerance:

Accuracy and Precision

Accuracy in CNC machining is the degree to which the dimensions of a machined object closely match the desired or target measurements. It displays the degree to which the CNC machine can reliably create pieces that adhere to predetermined tolerances. A number of variables must come together to achieve accuracy, such as precise programming, high-quality tools, and machine calibration.

Contrarily, precision deals with the machining process’s uniformity or reproducibility. It gauges how well different cuts or measurements match one another. A precise CNC machine can reliably replicate the same dimensions or features on several components with a negligible error margin.

Consistency and Repeatability

Using specified tolerances in CNC machining guarantees repeatable results. Manufacturers can produce many similar parts using dependable and repeatable methods, which minimizes variation and guarantees consistent quality throughout manufacturing runs.

Improved Product Quality

Tolerances applied in CNC machining greatly improve the quality of produced items. Parts that meet or surpass customer expectations in terms of fit, functionality, and overall performance are those that adhere to set specifications.

Cost-Efficiency

The efficient use of materials and resources is made possible by tolerance standards. CNC machining tolerance increases production’s cost-effectiveness by lowering the requirement for scrap or rework brought on by part variances.

Design Flexibility

More design freedom is possible when defined tolerances are used in CNC machining. More detailed features and geometries can be incorporated into designs by designers with the assurance that, within predetermined parameters, the CNC machining process will precisely manufacture these fine details.

Assembly and Interchangeability

Tolerance requirements make it easier for parts to be interchanged inside assemblies. When parts are made with the same tolerances, they can fit together easily, which simplifies assembly and guarantees correct operation.

Regulatory Compliance

Following certain tolerance levels is advantageous for industries like aerospace, automotive, or medical that are subject to strict regulations. Parts must comply with safety and performance standards in order to receive regulatory clearance and gain the trust of customers.

Increased Machining Efficiency

CNC machining procedures operate more effectively when realistic yet strict tolerances are imposed. By directing the selection of suitable tools, feeds, and cutting rates, these tolerances optimize the machining process and produce reliable, consistent results.

Decreased Inspection and Rework

The requirement for thorough inspection and rework is reduced when defined tolerances are met. Tolerance-abiding parts save time and money on inspection procedures, improving overall operational effectiveness.

Competitive Advantage and Customer Satisfaction

Competitive advantage and customer satisfaction are increased when manufacturers provide high-precision products that are within predetermined tolerances. Businesses can gain a competitive advantage in the market by providing dependable and superior products through consistent quality and precision.

Conclusion

There are many benefits to using CNC machining tolerance, and it has a big influence on the whole manufacturing process. Clearly specified tolerances provide improved product quality, design flexibility, and overall operational efficiency by guaranteeing accuracy, consistency, cost-effectiveness, and regulatory compliance. These benefits give enterprises a competitive edge in the market and enhance customer satisfaction in addition to streamlining production.